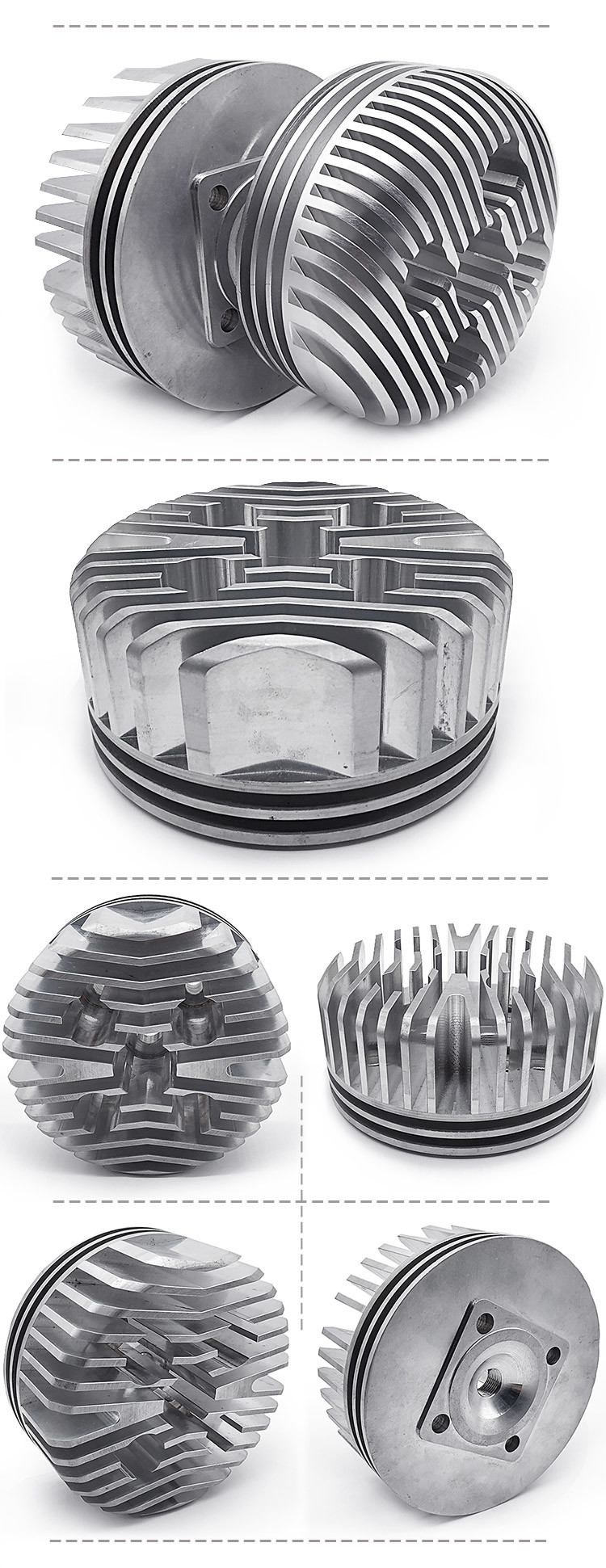

OEM Aluminum Milling Parts Services CNC Aluminum Machining

Features of OEM Aluminum Milling Parts Services CNC Aluminum

Machining

- High strength and hardness

- High thermal conductivity

- Outstanding EMI/RFI shielding properties

- Good finishing characteristics

- Good corrosion resistance

- High electrical conductivity

Application of OEM Aluminum Milling Parts Services CNC Aluminum

Machining

- Communication Equipment

- Industrial Equipment

- Medical EquipmentsMechanical Parts

- Auto Components Hardware Parts Auto Parts

- Ship Accessories

- Mechanical Equipment

- Electrical Equipment

Advantages of Yixin Precision Metal and Plastic Ltd

- Value-added services: A trusted partner who can help you purchase a variety of other

legal items, including a variety of special products.

- On Time Delivery: Sufficient production capacity and strong project management.

- Competitive Price: we are original manufacturer; low operating cost and innovative

ideas enable to offer very competitive cost.

- Quick Response: your inquiry will be replied in 24 hours, sales are more than 20

years of engineer background, react fast and give strong support.

- One-Step Service: offer from design, machining, surface treatment to finally

assembly.

- Production Capacity: 105sets Swiss Machining Lathes and 100sets 3/4/5 Axis CNC

machining centers with 500,000pcs monthly of sufficient production

capacity enable to meet large demand.

- Good Service: Good service runs throughout the whole process from

inquiry/quotation, sampling, production, inspection, packaging to

delivery and after sale.

- Quality Guarantee: Experienced engineers, precision production machines, precision

inspection equipment with experienced inspectors and QC system to

ensure quality.

Name | Detail | Optional |

| Material | GB, JIS, ASTM, DIN, AISI.EN,AS. | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper,

Titanium Alloy, Nylon, Acrylic, UHMWPE, PVC etc. |

| Shape | Plate, Tube, Rod. |

| Processings | Accept | Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC

Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting,

Laser Welding etc |

| Surface Treatment | Accept | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating,

Zinc Plating, Chrome Plating, Nickel Plating, Tin plating etc |

| logo | Accept | Silk print, Laser marking, UV print, Multicolor pad printing. |

| Size | 160*200*150mm. | Accept custom size. |

| Color | RAL, Pantone, RGB, CMYK. | White, black,silver, red, grey etc |

| Software | CAD, Solidworks, CATIA, UG, PRO-E. Inventor, AI |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

| Sample lead time | No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

| Pricing Term | FOB, CIF, DDP etc |

| Port of Loading | Shenzhen or Ningbo |

| Payment term | TT (30% in advance as deposit, balance before delivery), L/C, trade assurance order etc. Cost under 5000USD 100% prepay. |

Yixin Precision Ltd provide surface treatment - passivation

Passivation, also known as chromate treatment, is a pickling

process. It can remove oil stains, rust stains and oxides on the

surface by soaking or ultrasonic cleaning. Through the chemical

reaction of passivation solution, it can achieve the effect of

preventing corrosion and prolonging rust. Passivation film color

will change with different materials, passivation will not increase

the thickness of the product, so there is no need to worry that it

will affect the accuracy of the product.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining, but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost, but also affect

the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we

will choose suitable surface treatment process according to

different parts materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sand blasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy parts