OEM Parts CNC Services Aluminum Milling Machining

Features of OEM Parts CNC Services Aluminum Milling Machining

- Good finishing characteristics

- High strength and hardness

- High thermal conductivity

- Outstanding EMI/RFI shielding properties

- High electrical conductivity

- Good corrosion resistance

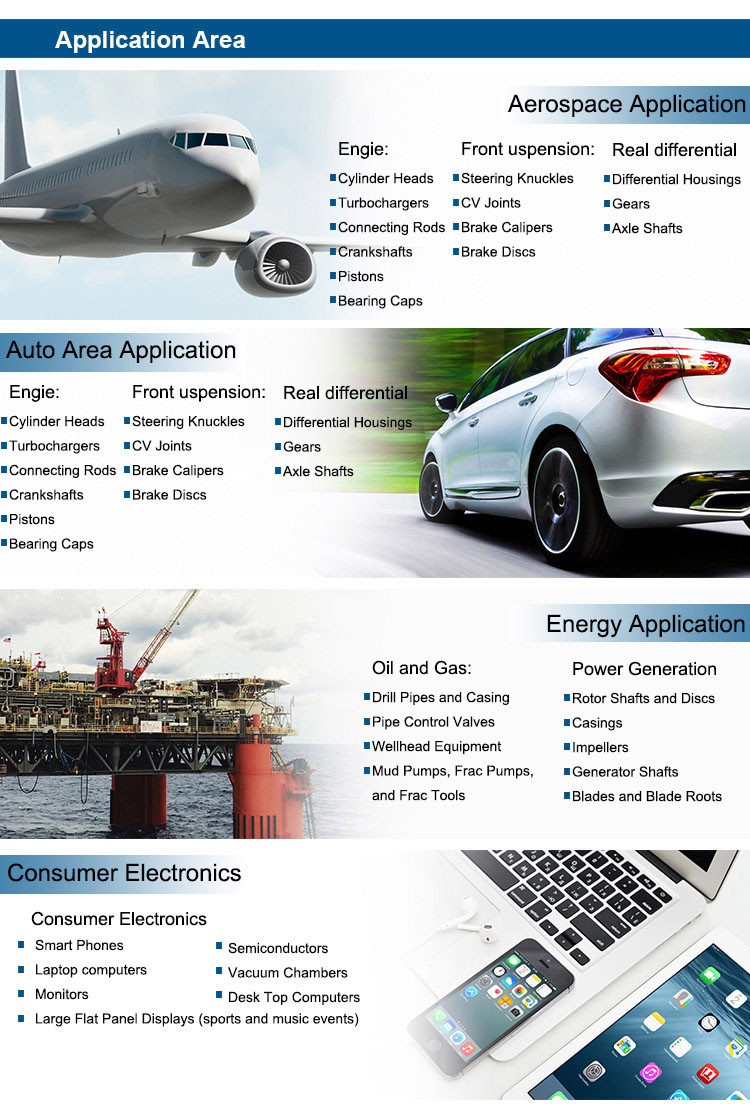

Application of OEM Parts CNC Services Aluminum Milling Machining

- Auto Components Hardware Parts Auto Parts

- Electrical Equipment

- Ship Accessories

- Medical EquipmentsMechanical Parts

- Mechanical Equipment

- Industrial Equipment

- Communication Equipment

Advantages of Yixin Precision Metal and Plastic Ltd

- On Time Delivery: Sufficient production capacity and strong project management.

- Competitive Price: we are original manufacturer; low operating cost and innovative

ideas enable to offer very competitive cost.

- Quality Guarantee: Experienced engineers, precision production machines, precision

inspection equipment with experienced inspectors and QC system to

ensure quality.

- Production Capacity: 105sets Swiss Machining Lathes and 100sets 3/4/5 Axis CNC

machining centers with 500,000pcs monthly of sufficient production

capacity enable to meet large demand.

- Good Service: Good service runs throughout the whole process from

inquiry/quotation, sampling, production, inspection, packaging to

delivery and after sale.

- One-Step Service: offer from design, machining, surface treatment to finally

assembly.

- Value-added services: A trusted partner who can help you purchase a variety of other

legal items, including a variety of special products.

- Quick Response: your inquiry will be replied in 24 hours, sales are more than 20

years of engineer background, react fast and give strong support.

name | Leaf spring |

type | OEM Stamping Parts |

Brand | YMP |

Material | Stainless steel |

Usage | Automobiles, gifts, handicrafts, plastics, tricycles, bicycles,

motorcycles, locks, electrical appliances, switches, molds, lamps,

toys, multi-purpose, fixtures, sofas, electronic communications |

Place of Origin | Guangdong, China |

Shipping | Sea freight |

Business Type | Manufacturer |

Packing | Outer Carton |

Main sales area | Europe, South America, Southeast Asia, North America, Northeast

Asia |

Sample or stock | Sample |

size | Customized Sizes |

Surface treatment | PaintingPowder CoatingPlatingPolishing |

Certificate | ISO |

Advantage | OEM / ODM / customized service provided |

What are PVDF parts? Processing method of PVDF material

The application of PVDF is mainly concentrated in three fields:

petrochemical industry, electronic and electrical industry and

fluorocarbon coatings. Because of its good chemical resistance,

processability, fatigue and creep resistance, it is one of the best

materials for petrochemical equipment fluid handling system as a

whole or lined pumps, valves, pipelines, pipe fittings, storage

tanks and heat exchangers.

Because of its good chemical stability and electrical insulation,

the manufactured equipment can meet the requirements of TOCS and

flame retardance, and it is widely used in the storage and

transportation of high-purity chemicals in the semiconductor

industry. In recent years, porous membranes, gels and separators

made of PVDF resin have been used in lithium secondary batteries,

and now this application has become one of the fastest growing

markets for PVDF.

Shenzhen Yixin Precision Medical and Plastic Ltd has accumulated 20 years' experience in the design and processing

of PVDF parts. The following are common processing methods of PVDF:

PVDF can be processed by general thermoplastic processing methods,

such as extrusion, injection molding, pouring, molding and transfer

molding.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining, but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost, but also affect

the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we

will choose suitable surface treatment process according to

different parts materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sand blasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy parts