Custom Metal Parts Fabrication Machining Center CNC Turning And

Drilling Parts

| Product Name | CNC machining parts |

| Part No. | YMP-191205-1 |

| Dimension | Customized |

| Material | Aluminum |

| Process | Milling, turning, Drilling, Grinding |

| Surface treatment | machined |

| color available | Silver, Red, Blue, Gold, Oliver, Black, White &, etc. |

| Tolerance | +/- 0.005 - 0.01mm / can also be customized |

| Surface Roughness | RA0.2-Ra3.2 / can also be customized |

| Application | All areas |

| Packaging | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton |

| Drawing Format | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

Quality Control Standards |

| To consistently exceed customer expectations, quality control and

assurance are achieved through |

| • Comprehensive written procedures and policies | • Fully equipped inspection department |

| • Detailed records of incoming raw material | • Consistent calibration and labeling of inspection tools |

| • Optional XRF analysis reports | • Designated areas for non-conforming parts |

| • Analysis of root cause of non-conformances | • Staff members being strongly encouraged to suggest |

| improvements in methods, materials, and suppliers |

What is the difference between laser engraving and silk screen

printing?

> > Laser engraving process forms LOGO and pattern on the

product by laser beam, and can also remove the surface treatment

coating of the product, which is concave. Silk-screen printing

products are raised by transferring logos and patterns to products

through ink adhesion.

> > The color of the LOGO and pattern of the laser engraving

process is the natural color of materials, while the color of the

LOGO and pattern of the screen printing process, that is, the color

of ink, is customizable.

> > In terms of wear resistance, the effect of laser

engraving is more durable than that of silk screen printing.

> > The cost is different, the laser engraving process is

more economical, because it doesn't need film, but screen printing

does.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

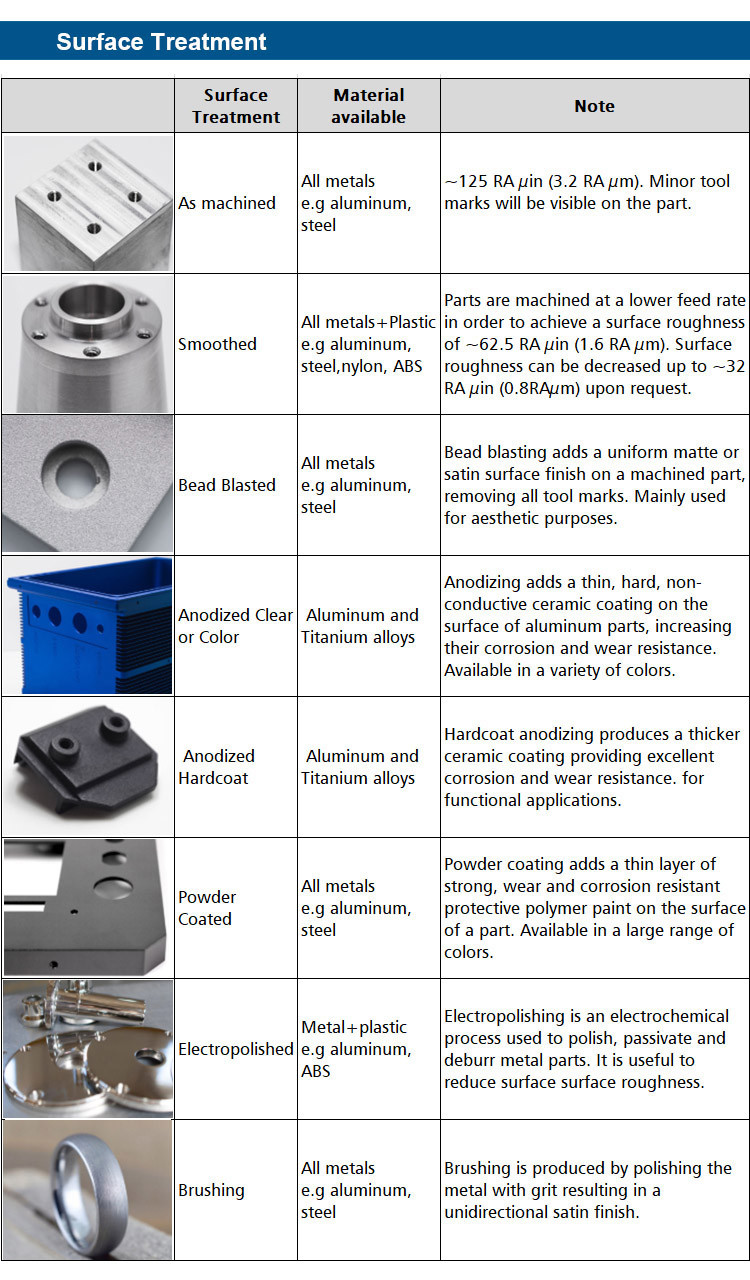

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining, but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost, but also affect

the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we

will choose suitable surface treatment process according to

different parts materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sand blasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy parts