Wholesale 5 Axis Precision Automatic Lathe Metal Aluminum Brass

Stainless Steel Turning CNC Machining Parts

Our company is located in Shajing Street, Shenzhen city, Guangdong

province, close to Hong Kong, and covers an area of 7000 square

meters. It is a high-tech model design and manufacturing enterprise

with the core of product model design and manufacturing and the

business purpose of providing all-around technical services.

YMP Industry was founded in 2004. After years of efforts, the

company has continuously expanded and changed. It has developed

from several initial employees to more than 50 professional

technical teams today.

Our factory has many years of custom processing experience hopes to

have the opportunity to cooperate with you. In addition, I

processed the team's superb skills and also provide customers with

a variety of customized processing services. Welcome customers from

all over the world to visit, guide, and negotiate cooperation.

| OEM Customized CNC Machining Parts of Most Materials |

| Quotation | According to the customer's drawings (size, material, thickness,

processing content, and required technology, etc.) |

| Tolerance | +/-0.005 - 0.01mm |

| Materials Available | Aluminum, Copper, Stainless Steel, Iron, PE, PVC, ABS, carbon

fiber, etc. |

| Surface Treatment | Polishing, Anodizing, Sandblasting, Deburring, Powder Coating,

Electrophoresis, etc. |

| Processing | CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing,

Surface Treatment, etc. |

| Drawing Formats | JPG, JPEG, PDF, AI, PSD, DWG, DXF, IGES, STEP |

| Quality Assurance | ISO 9001:2015 Certified. TUV |

| Capability | Precision CNC Machining, Sheet Metal Fabrication, Stamping, Plastic

Injection, Die Casting |

| Get a Free Quotation via Us >>>

Go |

| Material Available |

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron | Carbon Fiber |

| AL6061 | SS201 | C35600 | C11000 | POM | 20# | T300 |

| AL6063 | SS301 | C36000 | C12000 | Peek | 45# | T3008 |

| AL6082 | SS303 | C37700 | C12200 | PMMA | Q235 | T400HB |

| AL7075 | SS304 | C37000 | C10100 | ABS | Q345B | T700SC |

| AL2024 | SS316 | C37100 | etc. | Delrin | 1214/1215 | T800SC |

| AL5052 | SS416 | C28000 | | Nylon | 12L14 | T800HB |

| ALA380 | etc. | C26000 | | PVC | Carbon steel | T1000GB |

| etc. | | C24000 | | PP | 4140 / 4130 | M35JB |

| | C22000 | | PC | etc | M40JB |

| | etc. | | etc. | | etc. |

Yixin Precision Ltd provides surface treatment - Oxidation

It is an electrolytic oxidation process, which transforms the

surface of the material into a protective film, which makes it

difficult to oxidize and corrode, and can prolong its life and

achieve the appearance effect of various colors. Commonly used

oxidation treatments include ordinary anodic oxidation, wire

drawing oxidation, hard oxidation, thick film oxidation, micro-arc

oxidation, etc. Materials that can be oxidized include aluminum

alloy, magnesium alloy, titanium alloy, etc.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost but also affect

the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we

will choose a suitable surface treatment process according to

different parts materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sand blasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy partsQ1: What to be clearly indicated when I send you the drawing?

A: You are kindly requested to let us know the raw material,

finish, and quantity at least.

Q2: How large is your facility?

A: Our plant covers over 7,000 square meters of manufacturing

space, and over 30 highly experienced employees are located in

Humen Town of Dongguan City in the industrial capital of China.

Q3: Do you have multiple plants?

A: Yes, we have five plants, all the plants are located at a close

distance, it takes 10 minutes from headquarter to each plant. If

your project is up against a deadline, we can put your project on

the right machines, and the right plants with professional

expertise to provide you with a quality product.

Q4: Can you do prototype machining?

A: Yes, we run the quantity FROM 1 TO 100,000+ PARTS.

Q5: What size of a part can usually run?

A: Lathe machines can run parts up to 300mm in diameter and parts

up to 1500mm long. Milling machines can run parts up to 400mm in

diameter and parts up to 1200mm long.

Q6: What if we are not completely satisfied with the parts we

received?

A: We will replace any parts or components free of charge that you

are not satisfied with. We stand behind every part we provide. If

we make a mistake, we will make it right with you.

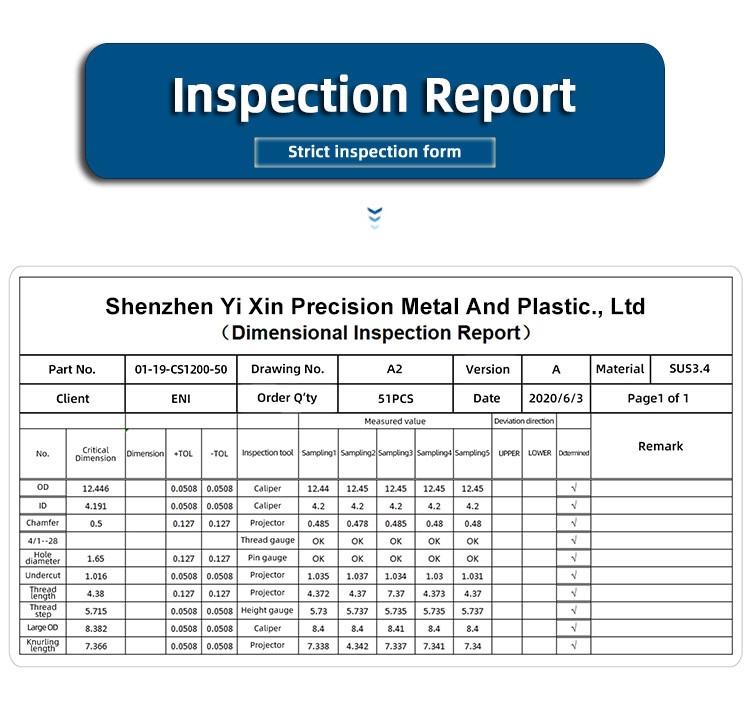

Q7: Do you offer proactive monitoring and reporting services that

can alert as to potential failures?

A: We have various types of inspection to assure quality;

1. IN-PROCESS INSPECTION;

2. OUTSIDE PROCESSING;

3. FINAL INSPECTION;

4. DOCK AUDITS.

If the defective part was received by the customer, QC manager will

investigate the results and root cause of the defect part, the

results of their investigation shall be documented on the C.C.A.R

form along with a recommendation of corrective action to prevent

recurrence. The report shall be forwarded to the plant manager for

concurrence and then distributed to all of the involved departments

for implementing. A written report detailing cause and Corrected

Action shall be forwarded to appropriate customer contact.

Q8: What is your procedure for returning defective product?

A: If the part cost is lower than the shipping cost, we will remake

the part and ship it to you ASAP, the expenses of the shipping cost

fell on us. If the defective part can be repaired or modified, we

would like the part ship to us using our FedEx or DHL express

account. Being honest and truthful is our business rule. If there

are out of specification parts, we stand behind every part we

provide, if we make a mistake, will make it right with you.