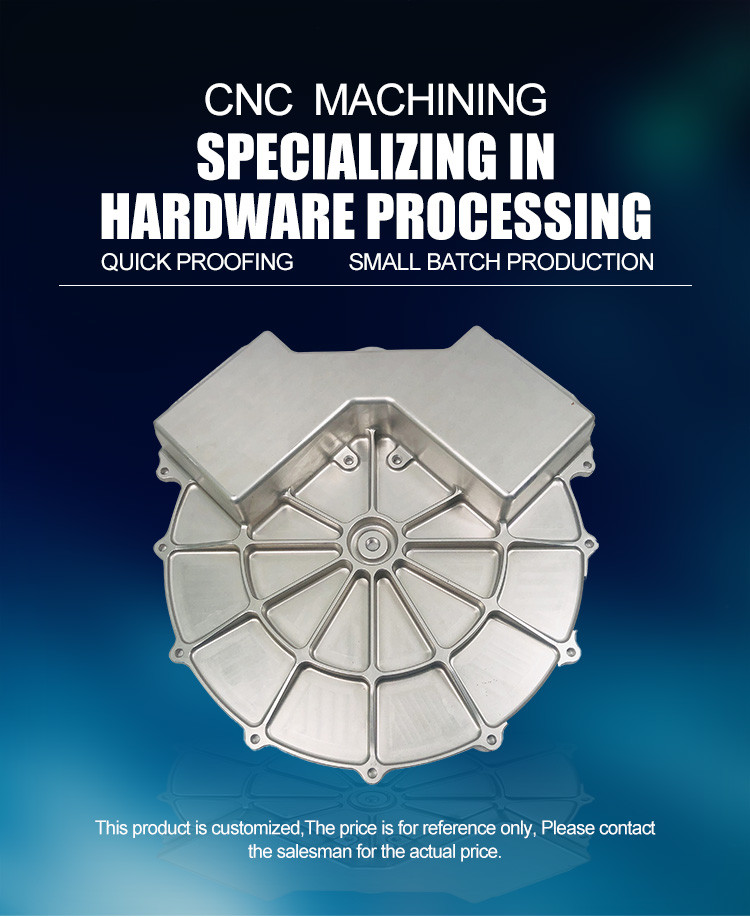

Shenzhen Dongguan Shaft Wheel Keyboard Lathe Product High Precision

Custom 5 Axis CNC Prototype Machining Aluminium Parts

YMP mainly processes precision parts and machinery parts,

manufactures parts of intelligent and automatic mechanical

equipment, and is engaged in import and export trade, with a lot of

production equipment and machines, such as milling machines, common

lathes machines, automatic feeding CNC lathe machines, CNC

machines, machining centers, drilling and tapping machines, buffing

machines, grinders, etc.

Therefore, we have the capabilities to make products of various

designs, sizes, and materials, and our products are at a low price

but of extremely high quality. Our quality inspectors strictly

adhere to the criteria of IQC, IPQC, and QA during inspection

processes. Inspecting the raw materials, monitoring the

manufacturing processes, and performing final inspections before

shipment is our daily work.

Our company is located in China's special economic zones-Shenzhen

City Baoan District, with a plant area of 7,500 square meters and

more than 100 employees. And with customers mainly in Japan,

Europe, and South East countries. Customers' need is always our

priority.

Mold Material | YMP-cr12 |

Material | 1) AL1060, AL6061, AL6061, AL5052 etc.

2) Steel, mild steel, SPCC, etc. 3) SS201, SS303, SS304, SS316, SS316L etc. 4) SPTE, galvanized sheet, etc. 5) Brass, copper, etc. |

Specification | 1) According to customers' drawings

2) According to customers' samples |

Processing | Laser cutting, bending, welding, stamping, riveting, assembly,

packing, etc. |

Surface Finish | Polishing, galvanizing, powder coating, anodizing, electroplating,

brushing, silk screen, etc. |

Drawing format | DWG, DXF, Stp, Igs, PDF, Jpg, etc. |

Service Type | OEM&ODM |

Certificate | ISO9001, SGS, TUV |

Factory area | 7500 square meters |

Sample | Available before mass order |

Industries Served | Agriculture Machinery, Farms, Furniture, Power, Appliance, Auto,

Building, Solar Energy, Instrumentation, Medical device. |

Guidelines for CNC Machining of Precision Parts

Yixin Precision CNC Machining Factory believes that in the design

of process standards, the correct selection of positioning data has

a crucial impact on ensuring the processing requirements of parts

and arranging the processing sequence reasonably.

The reference is divided into fine datum and rough datum: the rough

reference is used as the positioning reference with the unmachined

appearance on the blank. The fine reference takes the machined

appearance as the positioning reference.

01 criteria for selecting a fine benchmark

(1) Benchmark coincidence criterion: the processed surface design

data should be selected as accurately as possible to prevent data

dislocation from forming positioning error.

(2) Consistent datum criterion: in order to ensure the relative

orientation accuracy between the machined surfaces, as many

surfaces on the workpiece as possible should be processed using the

same set of fine benchmarks.

(3) Benchmark criterion of workpiece machined surfaces: the

repeated machining method of two machined surfaces can be used as a

mutual reference.

(4) Self-reference criterion: Some surface finishing processes

requires small and uniform machining tolerance, and the machined

surface itself is often used as the precision benchmark.

The four criteria mentioned above for selecting fine benchmarks are

sometimes not satisfactory at the same time and must be decided

according to the actual situation.

02 Criteria for selecting rough benchmarks

(1) The rough benchmark should be used in the first workpiece

processing. Whether the rough benchmark is selected correctly is

not only related to the processing of the first working procedure

but also has a great influence on the whole working procedure of

the workpiece.

(2) Principle of reasonable distribution of machining tolerance:

the machining allowance of workpiece appearance should be uniform,

and the important appearance should be taken as the rough

benchmark.

(3) Easy-to-install clamp rule: In order to make the workpiece

position stable and clamp firmly, Yixin Precision reminds you that

the approximate reference point to be selected should be as smooth

and clean as possible, free from lightning strikes, and the forging

cut or other defects allow a satisfactory supporting area.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost but also affect

the time to market products.

YMP has rich experience in the surface treatment of metal parts,

and we will choose a suitable surface treatment process according

to different parts' materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sandblasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy partsWHAT'S THE ORDER PROCESS?

1)Inquiry--provide us with all clear requirements (total qty and

package details).

2)Quotation--an official quotation form with all clear

specifications from our professional team.

3)Marking Sample--confirm all quotation details and the final

sample.

4)Production--mass production.

5)Shipping--by sea or by air.

WHAT TERMS OF PAYMENT DO YOU USE?

As for the payment terms, it depends on the total amount.

HOW DO YOU SHIP THE PRODUCTS?

By Sea, By Air, By courier, TNT, DHL, FedEx, UPS Etc. It is up to

you.

WHAT IS THE AVERAGE DELIVERY TIME?

Sample usually takes about 10-20days depending on product type.

Bulk order usually takes about 35 days.

HOW WOULD I GET A PRICE LIST FOR A WHOLESALER?

Please e-mail us, and tell us about your market with MOQ for each

order. We would send the competitive price list to you ASAP.