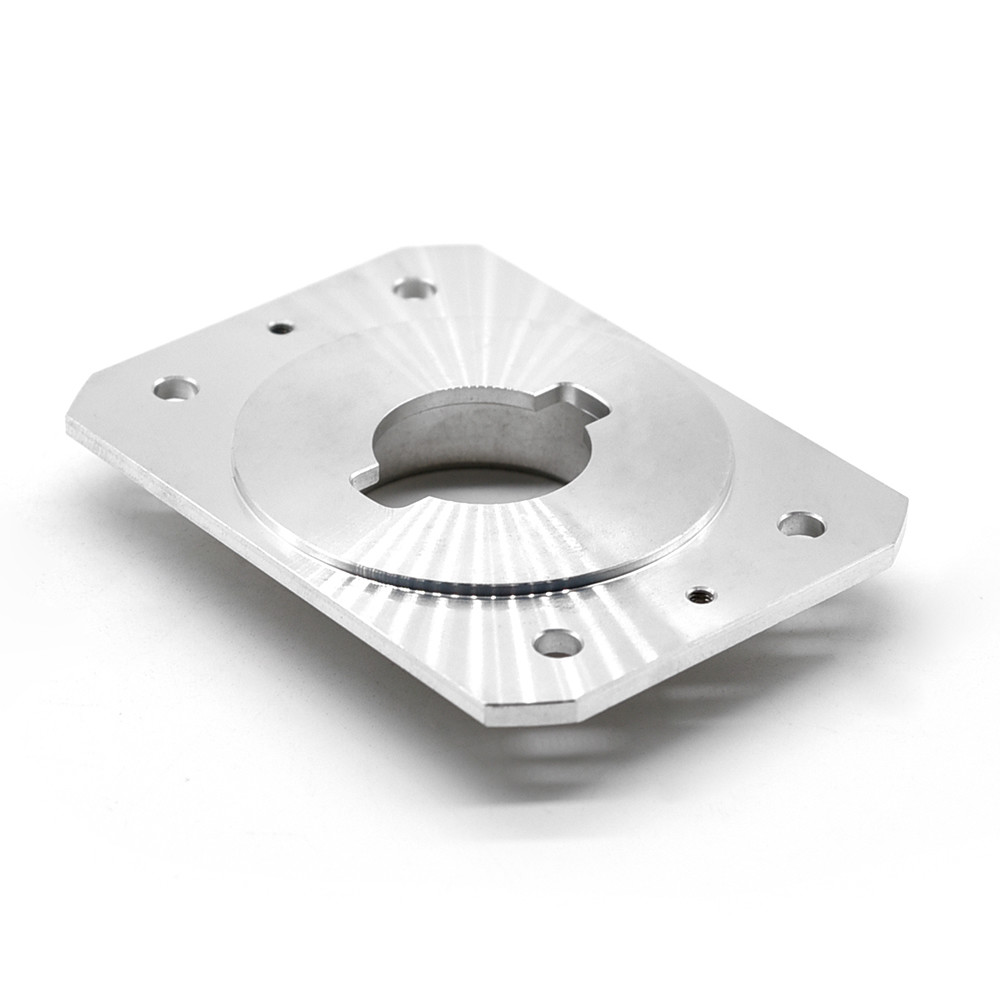

Yixin Precision Metal Machining Factory Customize Turning Cutting

Aluminum Sheet Fabrication Parts

Features of Xielifeng Metal Machining Factory Customize Turning

Cutting Aluminum Sheet Fabrication Service

- High strength and hardness

- Good corrosion resistance

- High thermal conductivity

- High electrical conductivity

- Good finishing characteristics

- Outstanding EMI/RFI shielding properties

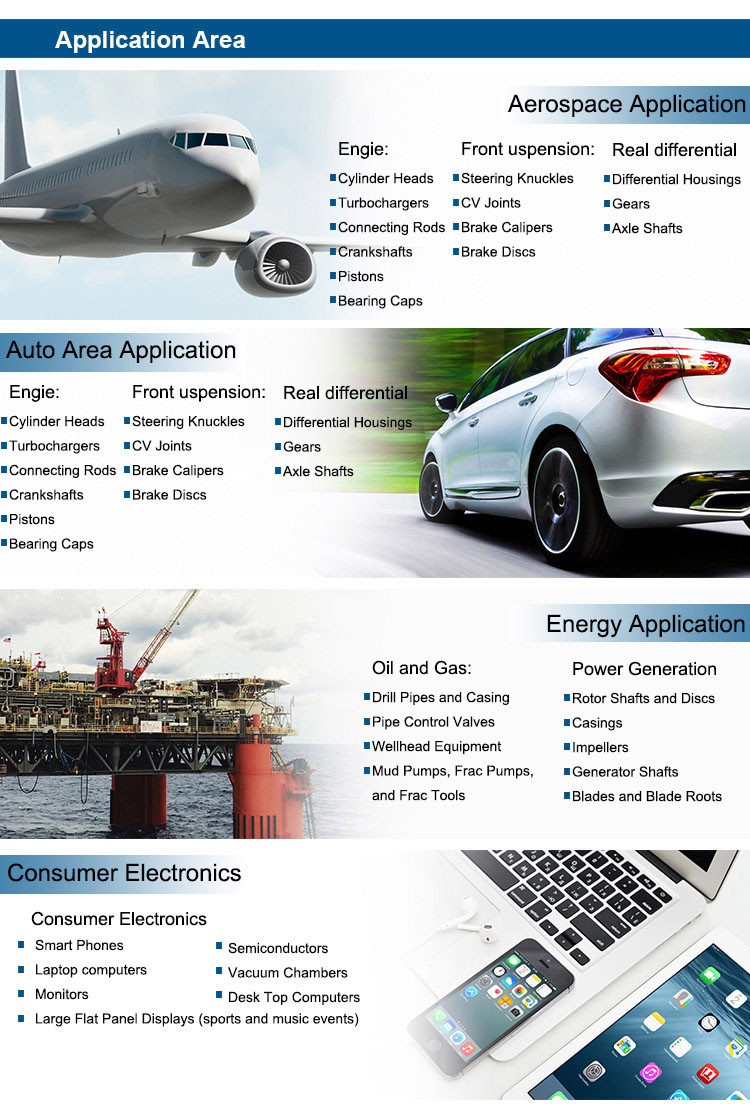

Application of Xielifeng Metal Machining Factory Customize Turning

Cutting Aluminum Sheet Fabrication Service

- Communication Equipment

- Mechanical Equipment

- Auto Components Hardware Parts Auto Parts

- Electrical Equipment

- Medical EquipmentsMechanical Parts

- Industrial Equipment

- Ship Accessories

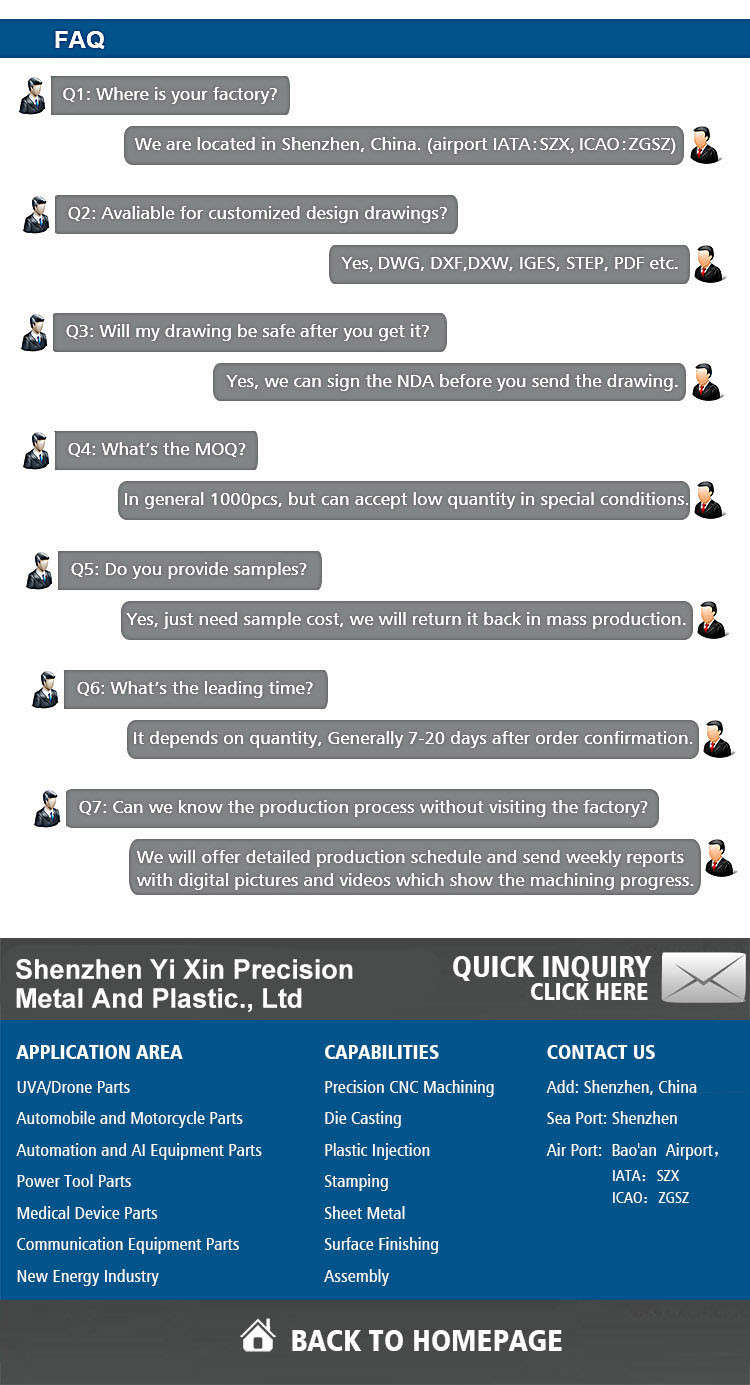

Advantages of Yixin Precision Metal and Plastic Ltd

- Quick Response: your inquiry will be replied in 24 hours, sales are more than 20

years of engineer background, react fast and give strong support.

- Value-added services: A trusted partner who can help you purchase a variety of other

legal items, including a variety of special products.

- Competitive Price: we are original manufacturer; low operating cost and innovative

ideas enable to offer very competitive cost.

- On Time Delivery: Sufficient production capacity and strong project management.

- Good Service: Good service runs throughout the whole process from

inquiry/quotation, sampling, production, inspection, packaging to

delivery and after sale.

- One-Step Service: offer from design, machining, surface treatment to finally

assembly.

- Quality Guarantee: Experienced engineers, precision production machines, precision

inspection equipment with experienced inspectors and QC system to

ensure quality.

- Production Capacity: 105sets Swiss Machining Lathes and 100sets 3/4/5 Axis CNC

machining centers with 500,000pcs monthly of sufficient production

capacity enable to meet large demand.

| Product Name | Customized Sheet Metal stamping part |

| Material | SPCC,mild steel, stainless steel, aluminum |

| Machining Equipment | laser cutting machine, bending machine, welding machine, 3-5 axis

CNC milling machines, CNC lathes, EDM machines, Grinding machines. |

| Finish | painting, powder coating, plating, plising, anodize |

| Inspection equipment | CMM, Tool microscope, multi-joint arm, Dial gauge, Marble platform,

Roughness measurement, Digital height gauge, caliper, Projection

machine, Hardness tester and so on. |

| Drawing Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Packaging | 1.Standard strong carton package + Pallet/ Wooden case |

| 2. Per customer's requirements |

| Delivery | Sample: 5-10 days |

| Mass Production: 15-30 days depends on quantities |

| Application | Aerospace, Aviation, Agriculture, Marine, Electronic, Automobile,

Communication, Drone, Medical, Solar energy, Home Appliance, etc |

Quality control process of CNC aluminum alloy parts processing

At present, with the rapid development of all walks of life, the

market demand for precision aluminum alloy parts is increasing, the

product shape and structure are becoming more and more complex, and

the industries for which aluminum alloy parts are applied are

becoming more and more extensive. Customers are demanding higher

and higher product quality and delivery time. Then, quality control

has become the first consideration of CNC manufacturers. Regarding

quality control, Yixin Precision does this.

First, the selection of raw materials; The characteristics and

functions of different materials are different, which guarantees

the functions of parts, and the purchased raw materials must meet

the requirements of customers. Yixin Precision selects the most

suitable aluminum alloy material for processing after the 3D

drawings, samples and requirements provided by customers.

Secondly, it is the aluminum alloy processing technology; At

present, the advanced CNC machining center in the machining

industry is used for processing, which is characterized by small

error, high precision and fast product forming speed, and can

process precision parts with complex shapes and structures. After

the aluminum alloy is processed, it will be polished by the manual

department to make the surface of the product bright and round.

Finally, it is quality inspection; Hand-finished product surface

treatment and initial inspection will be delivered to Yixin

Precision Quality Inspection Department for quality inspection of

the whole product. This step consists of three steps: size, weight

and appearance of aluminum alloy parts. After quality inspection,

they are packaged and mailed to customers. Ensure that the products

delivered to customers meet the requirements or even exceed

customer expectations.

Yixin Precision has been engaged in the machining industry for more

than 20 years, with 165 sets of advanced CNC machining centers,

cooperated with more than 3,000 enterprises, and has a professional

technical team and pre-sales and after-sales service system. We

provide customers with one-stop processing services.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining, but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost, but also affect

the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we

will choose suitable surface treatment process according to

different parts materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sand blasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy parts